-

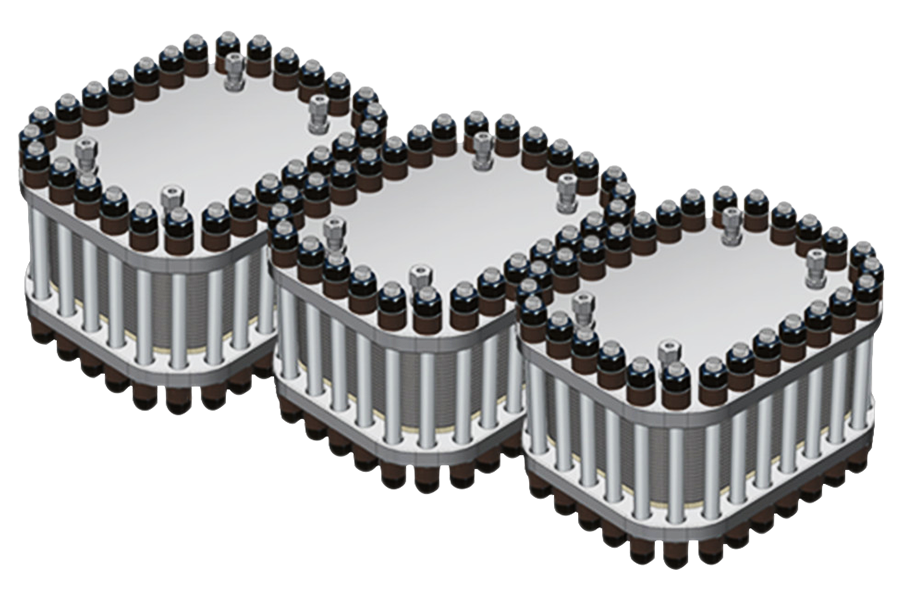

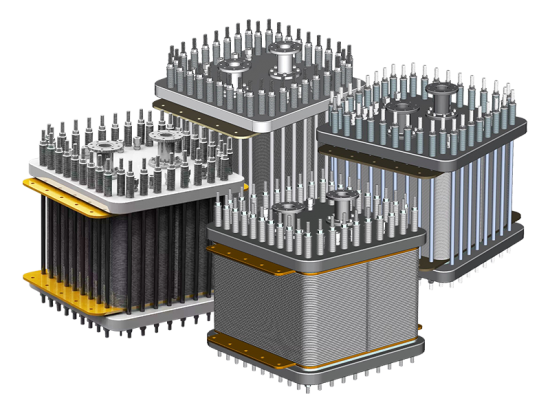

Modular

and scalableInterlocking units stack to easily scale from megawatts to gigawatts.

-

Compact

and portableStandard modular “human-sized” units are easy to transport and quick to install.

-

Safe

and durableBuilt to minimize safety risks and withstand the elements.

-

High plant

availabilityStandard modular units ensure higher plant availability and system reliability.

-

Optimized

integrationDynamic and efficient operation that responds quickly to intermittent renewable energy resources.

-

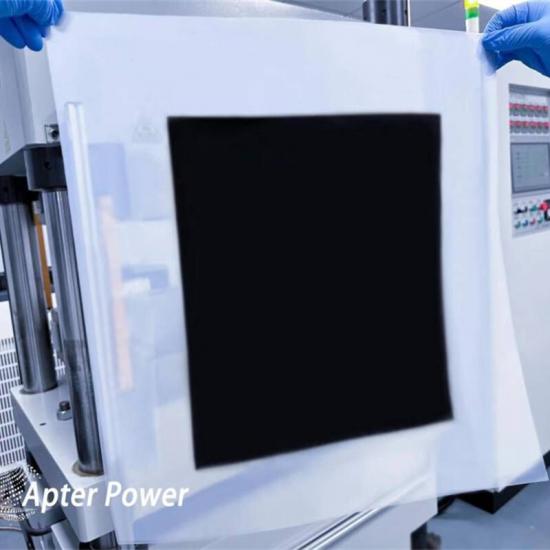

Customized

end productHydrogen customized to meet varying purity and moisture content requirements.

*International Renewable Energy Agency (IRENA) Research

IPv6 network supported

IPv6 network supported